Mt. Kaguyama, located along the Yoshino River, is a location that inspired poetry that was written in the ancient Manyoshu Poetry Collection.

At the foot of this mountain, there is a very famous store that sells a certain type of specialty product

It is a store that is crowded with many people every spring.

So what is this product?

The answer is the school bag.

In this article, I would like to introduce “Bag Workshop Yamamoto,” a manufacturing and sales company for school bags that not many people know about.

Reservations for school bags start a year ahead of time and spring is the hottest season for this showroom.

Families with children who will enter school the following spring come one after another to preview the school bags here. The reason for this shop’s popularity, despite the inconvenience of its location, is in the high quality of the school bags sold here.

Bag Workshop Yamamoto was founded in 1949, so its history is also the history of postwar Japan. After the war, the founder (and predecessor to the current owner) valued, “making good products, regardless of the time that must be sacrificed to do so.” The second and present owner of the workshop inherited the teachings of the previous generation and continued with the philosophy of pursuing “reliable manufacturing.”

The careful construction of bags, which is enabled by advanced technology and careful attention to every detail, has gradually gained popularity and now Bag Workshop Yamamoto has become popular.

This is the most popular bag for girls, known as the “Raffine” bag. Possessing a fine balance of refinement and cuteness, It’s calm colors and tiara stitching are impressive.

For those who are thinking “I know their products are great, but I have no use for a school bag…” there is a select shop known as the “Kaguyama Bag Store” (featuring other types of bags) located in the showroom, which is also directly operated by Bag Workshop Yamamoto.

The products in the select shop are all directly purchased by the bag workshop, so everything is high quality and well designed. In fact, I saw a father, who came to choose his child’s school bag but ended up eagerly listening to the explanation of a business bag the next moment I ran into him.

In addition, you can also get a closer look at the bag making process at Bag Workshop Yamamoto by joining a tour. In the bag industry, the manufacturing system for products is often divided up between different locations, but at Bag Workshop Yamamoto, all school bags are produced in-house from the beginning to the end. In fact, the workshop is actually just a 3 minute walk from the showroom. The landmark for the workshop is the 400-year-old camphor tree standing on its premises.

The most striking thing in the workshop is the widely used red leather material. It is cowhide. Can you tell? The back of the bag uses leather from the head of the cow, the front is made from the buttox, and the left side from the back of the animal. The leather on the back is hard and tough and the leather on the stomach is soft and can easily expand and contract. For the cover (which sees the most use when opening and closing the school bag), firm and sturdy leather taken from the back of the cow is used. Furthermore, it seems that the material for the top and bottom of these bags is also properly thought-out.

During the process of making a bag, a craftsman carefully checks the back of the leather to look for small scratches and twists. For me (an amateur at all of this), there seemed to be no scratches from what I saw. Moreover, I don’t think you need to worry about the small scratches and twists, either. But this is wrong. In fact, this is actually the most important step that requires the most caution in the making of a school bag. If they overlook the scratches in this process, it will lead to a big defect later. So in order to make good school bags, they check each one using both their hands and eyes. This is an important process that can only be performed by craftsmen who are familiar with the characteristics of leather.

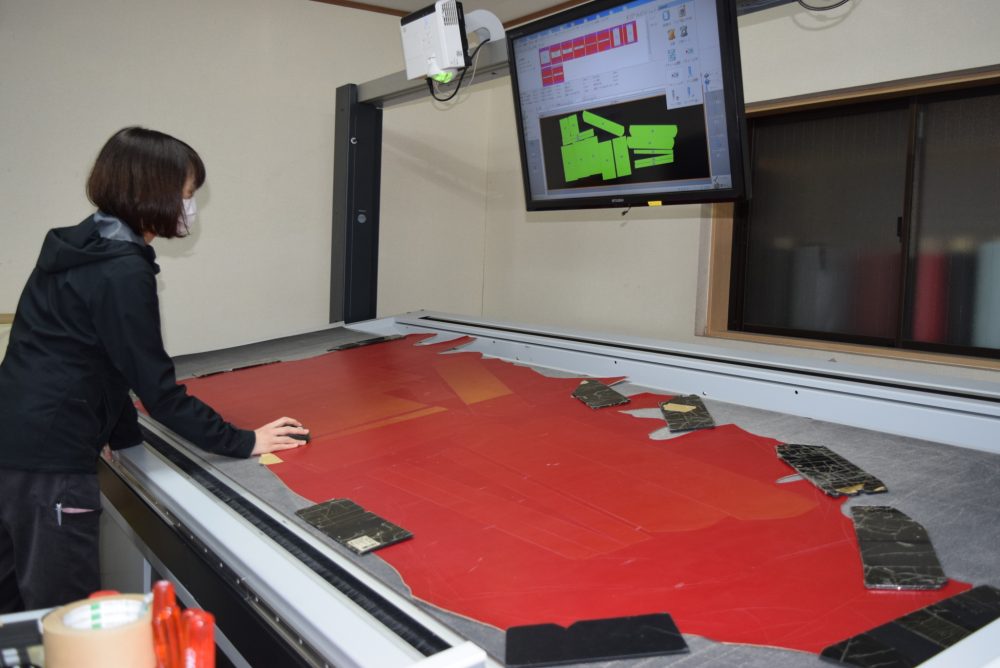

This is the process of cutting which is done by looking at a monitor, specifying the place to cut and then making the cut with the pneumatic cutter. How quick! How beautiful! Apparently, this automatic cutting machine was made in Germany and is the latest model (of which there is only one in the entirety of Japan).

This machine also completes the important process of finishing the leather. When this is all done, the leather will be thinned to a thickness of 0.005 mm or less.

The next step is the varnishing and Bag Workshop Yamamoto is very particular about this process. After polishing and smoothing the cut edges of the leather, the process of varnishing and polishing is repeatedly done to create a smooth and beautiful surface. It seems that this sort of work requires a level of craftsmanship that demands real experience. The finished varnish is uniform and beautiful. Its vibrant color also accents the school bags and is very fashionable.

This leather cover-making technique, where the leather is pulled from the corners like a fan, is known as “kizami.” This process requires a lot of labor and high skill, so it can be said that it is one of the qualifying criteria for the high quality of the bags. The craftsmen also make these beautiful folds one by one by hand.

Each completed part of the bag is firmly sewn together with a thick needle that is the size of the core of a ballpoint pen. From one process to another, like the passing of a relay baton, each craftsman’s thoughts are combined to create a school bag. It feels like you can almost see the smiles of the children receiving the “baton” at the end.

There are about 40 craftsmen in the workshop, including the 2nd-generation owner. The inspiration for making school bags originated from when the present owner used his expertise to make a custom navy blue school bag for his eldest son. He continued to make school bags for both his second son and eldest daughter as well. It is said that the joy of creating while thinking of the smiles of the recipients still supports the “heart of manufacturing” at Bag Workshop Yamamoto.

In recent years, Bag Workshop Yamamoto has been focusing on manufacturing and selling original leather products in addition to manufacturing school bags and selling supplies.

Here is just one example. From the left, a business card case (rapeseed flower color) and a coin pouch (pine needle color crossed with the color of new leaves).

The deerskin used for these products comes from Fujioka Yukichi Honten, which has a 130-year history and is based in Uda City, Nara. It comes in elegant colors and has a soft touch.

What will this excellent workshop produce next? I can’t wait to find out.

Bag Kobo (Workshop) Yamamoto

Address: 899 Minamiura-cho, Kashihara-shi, Nara 634-0022

TEL: +81-744-20-1771

HP: https://www.kabankobo.com/

Business hours: 10:00 ~ 17:30

Workshop tour: Tuesday, Thursday, Friday and Saturday

(10:10-12:10, 13:00-15:00, 15:00-17:10)

Regular holiday: Wednesday (except national holidays), year-end and New Years holiday

Parking: YES

Access:

By bicycle: 15 minutes from Kintetsu Kashihara-jingumae Station East Exit

By bus: About 25 minutes from Kintetsu Yamato Yagi Station, and 1 minute walk from the “Minami-uracho” stop